Identifying flow problems in silo design

Common silo flow problems ✓ bridging ✓ core flow/funnel flow ✓ time consolidation ✓ segregation ✓ fluidization

Bridging

A stable, self-supporting arch above the outlet prevents material from discharging.

This usually occurs with fine, cohesive bulk solids. Adhesive forces between particles

create bulk strength that blocks flow into the outlet region. High wall adhesion or

shallow hopper slopes can exacerbate the effect. With decreasing hopper diameter the

supporting effect of wall friction increases and a critical outlet can form a bridge.

- Outlet blockage

- No or strongly reduced flow

- Caking / buildup

- Time consolidation

- Larger outlet opening

- Steeper hopper slope or changed geometry

- Different wall material or coating to reduce friction

- Material modification (particle size, moisture, additives)

- Discharge aids (vibration, air pulses, mechanical devices)

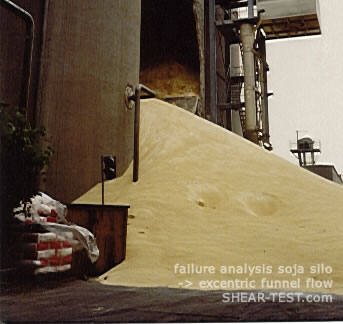

Core flow / Funnel flow

Material flows primarily through the central channel while wall flow is slowed or arrested. If adhesive forces at the wall exceed the internal shear strength of the bulk solid, the wall layer remains and the central channel discharges.

- Uneven discharge

- Segregation

- Uncontrolled or irregular flow

- Unequal residence times and dead zones

- Increased risk of caking and time consolidation

- Uneven wall loading

- Overloading of discharge devices by falling material

Design the silo to promote mass flow so that the whole inventory moves uniformly:

- Optimize geometry (hopper slope, outlet size)

- Reduce wall friction (different wall materials, coatings)

- Material modification (particle size, moisture, additives)

- Use activation/discharge aids to engage a larger discharge area

Time consolidation

While stored at rest, physical or chemical processes (e.g. crystallization) can strengthen particle contacts and wall adhesion. This increases bulk strength over time and negatively affects flow. During subsequent discharge the material may no longer flow freely, leading to bridging, core flow or irregular discharge. Areas with longer residence times are also prone to time consolidation.

Problems:- Buildup / caking

- Bridging

- Irregular flow

- Increased structural load

- Regular activation of the material (e.g. periodic discharge activation)

- Material modification to reduce consolidation tendencies (moisture control, temperature)

- Optimize geometry to promote mass flow

Segregation during filling

During filling different particle sizes and densities behave differently. Coarser or denser particles tend to travel further while finer or lighter particles remain near the inlet. This leads to an inhomogeneous bed and may promote core flow, funnel flow or eccentric discharge, negatively affecting product quality.

Problems:- Uneven material distribution

- Increased or eccentric loads on the structure

- Uneven product composition at the outlet

- Reduced product quality

- Higher process variability

- Avoid segregation by appropriate filling strategies

- Material modification to reduce particle disparities

Segregation during discharge

Discharge can also cause segregation since different particles move differently. Coarser particles may flow preferentially while finer ones are impeded by interparticle contacts, resulting in an uneven outlet composition and potential quality issues.

Problems:- Uneven outlet composition

- Quality degradation

- Increased process variability

- Promote mass flow to minimize segregation effects

- Optimize geometry and wall materials

- Material modification to reduce particle differences

Fluidization

Fine, light particles can be entrained by air during filling or rapid flow (e.g. core flow) or when a collapse in the channel occurs. The bed can become partially fluidized and behave like a fluid, causing uncontrolled flow or 'shooting' through discharge devices. Short residence times can also prevent complete degassing of the material; some discharge aids such as aeration may inadvertently cause fluidization.

Problems:- Uncontrolled material flow / shooting

- Shooting through discharge devices

- Dust generation

- Overloading

- Sufficient residence time for degassing

- Avoid core flow or channeling where possible

- Controlled aeration to prevent fluidization

Eccentric loading

Asymmetric flow due to uneven filling or segregation can produce core/funnel flow and cause loads that are not uniformly distributed on the silo walls. During discharge one side may empty faster than the other leading to local overstress and potential structural damage.

- Uneven load distribution

- Increased stresses in localized areas

- Potential structural damage or deformation

- Reduced design life

- Select appropriate discharge device to uniformly activate the outlet

- Avoid segregation

- Reinforce structure where needed

- Optimize geometry to promote mass flow

Measurements for silo design

Many of the problems described above can be avoided by correct geometry and design that favour mass flow. We identify root causes and advise on concrete countermeasures to achieve reliable material flow in your silos.

Determining physical material properties enables prediction of behaviour and impacts on the surrounding system. These parameters are essential for material characterisation, bulk solids technology and product design and give engineers the confidence to design safe bulk handling equipment (silos, discharge units, …).

Measured material data are the key to safe silo design. DIN EN 1991-4 explicitly recommends that "measured values are preferred over estimated or tabulated values." We provide these precise measurements for your technological silo design.

DIN EN 1991-4 requires measured material data

Section 4.1.2 of DIN EN 1991-4:

"Characteristic values of bulk material properties should be determined on the basis of experimental results. Measured values should be preferred to estimated or tabulated values."

Conclusion: Safe silo designs require precise measured data - not table values or estimates!

Professional bulk solids measurements for your silo design

Need a precise characterisation of your bulk solid? Our laboratory offers standard-compliant measurements for safe silo design according to DIN EN 1991-4.

- ✓ Over 30 years of experience

- ✓ Standard-compliant measurements

- ✓ Detailed evaluation reports

- ✓ Complete material data determination