Flowability Factor (FL, FLR, FLA, ffc)

Flow factor measurement ✓ Definition & calculation ✓ Hopper design ✓ Flow properties ✓ Material handling technology ✓ Bulk materials

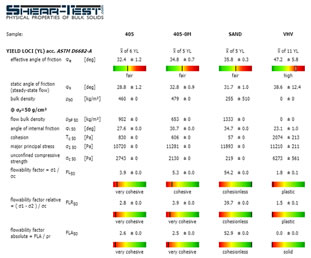

The determination of yield loci provides key mechanical parameters for describing the flow behavior of bulk solids. Typical parameters include the principal stresses (σ1, σ2), unconfined compressive strength (σc), tensile strength (σt), internal friction angle (φi), and cohesion (Τc).

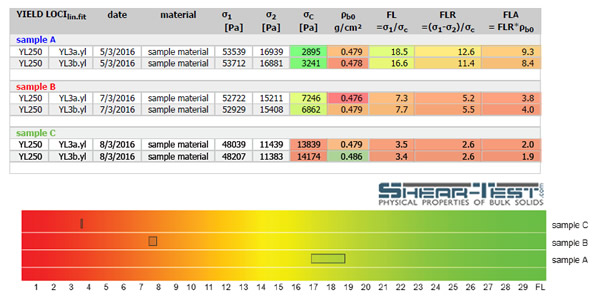

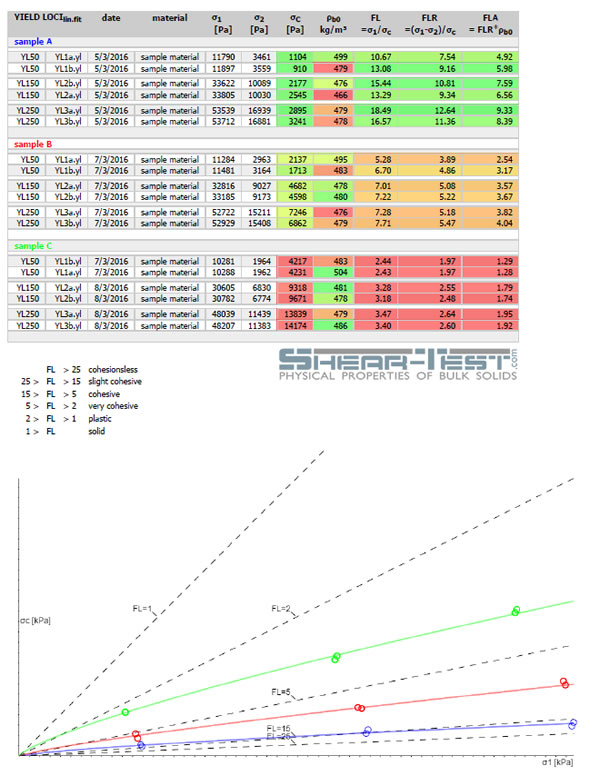

The flowability factor is a dimensionless parameter for quickly classifying powders and bulk solids regarding their flowability and assessing their suitability in process engineering applications. To classify powders and express flowability in a single parameter, the flowability factor (FL = ffc = σ1/σc) is commonly used as the ratio of the major principal stress to the unconfined compressive strength.

Since the compressive strength σc always depends on the consolidation state, comparison values are only meaningful if determined at the same consolidation stress σ1. The flowability factor allows a pragmatic classification but shows a nonlinear sensitivity to the underlying measured values and should therefore be interpreted in the context of other parameters.

The categorization of bulk solids based on the flowability factor (FL) is as follows:

| FL | > 25 | cohesionless | |

| 25 > | FL | > 15 | slightly cohesive |

| 15 > | FL | > 5 | cohesive |

| 5 > | FL | > 2 | very cohesive |

| 2 > | FL | > 1 | plastic |

| 1 > | FL | solid |

The relative flow factor (FLR) considers the difference between the major and minor principal stress in relation to the compressive strength and is calculated as: FLR = (σ1 - σ2) / σc. This parameter is particularly sensitive to materials with pronounced internal friction and complements the classic FL.

Since the flowability factor is only partially comparable for bulk solids with different densities, an advanced version is often used. This considers the different densities of the bulk solids and enables a more precise classification. The absolute flowability factor (FLA) is defined as the product of the relative flow factor (FLR) and the bulk density (ρb0) of the material. FLA = FLR * ρb0. By including the bulk density, comparability between materials with different densities is improved, leading to a more precise classification of flow properties. In practice, the absolute flowability factor (FLA) is often used instead of the relative flow factor (FLR).

The classification of bulk solids based on the flowability factor provides a quick and easy way to assess flow behavior. However, it should be noted that this factor alone does not capture all aspects of flow properties. For a comprehensive analysis, further mechanical parameters and the specific application environment should be considered.

Bulk solids with similar flowability factors should exhibit similar flow behavior in application. Higher values indicate better flow properties, while lower values indicate restricted flowability, requiring verification of silo flow or processing capabilities.

This method provides a way to ensure the usability of process technology during product changes or for different batches of raw or finished materials.

Flow Function

By measuring several yield loci at different consolidation stresses, the flow function is obtained, describing the flow behavior of a bulk solid over a wider stress range.

The flow function is used for further technological calculations (e.g., determining the minimum outlet opening in a hopper). To determine it, yield loci are measured at at least three different consolidation stresses covering the application range. The flow function is often represented by a linear equation, which facilitates further calculations. However, a curved trend is often observed at lower stress ranges, which is also due to the fact that the compressive strength (σc) cannot be greater than the major principal stress (σ1). A flowability factor less than one is therefore not possible.

At higher stresses, bulk solids may exhibit altered flow properties due to saturation effects, decomposition, or abrasion. Clumping or similar effects can also occur and affect flowability. By measuring over a larger stress range, these effects can be made visible and application safety ensured.

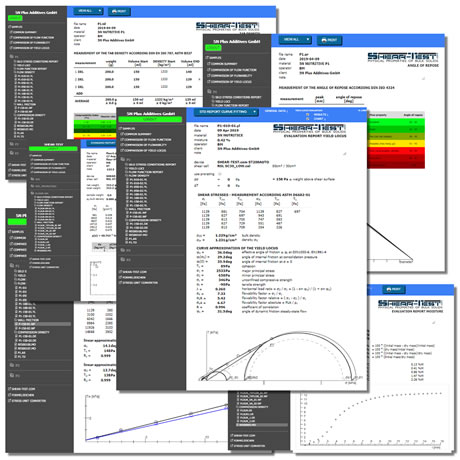

Flow functions with associated flowability factors for three different materials.

Automatically generated analysis of the flow function(s) according to the measurements.

Application Example:

The flowability of a bulk solid directly influences the discharge rate from silos, hoppers, or other containers. Good flowability enables smooth material flow, while poor flowability can lead to problems such as arching, core flow, or even funnel flow, resulting in irregular material flow. This can affect the efficiency of production processes and lead to downtime.

If the flowability of a bulk solid changes, e.g., due to moisture uptake, particle changes, or other influences, it can affect the function of the entire plant. Therefore, it is important to monitor flowability during ongoing processes or product changes to ensure smooth operation.

Flowability Analysis by Our Laboratory

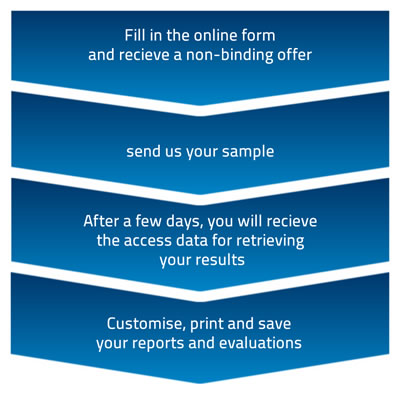

We offer fast and simple control of the flowability of bulk solids for product changes or raw material changes.

- ✓ Time-saving execution

- ✓ Application safety

- ✓ High measurement accuracy