Measurements for Powders & Bulk Solids

- Powder characterization

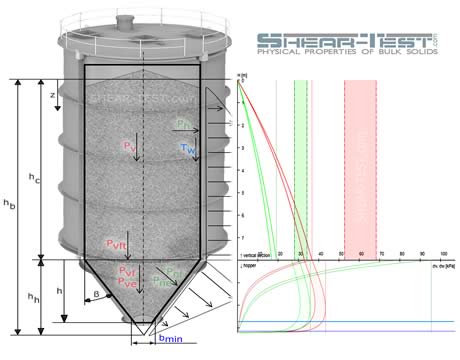

- Technological design of silos and bulk solid containers

- Silo calculations according to DIN EN 1991-4

- Design of conveyor systems (screw conveyors, pneumatic conveying)

- Problem solving in existing silos

- Identification of flow problems

- Comparison of flowability of bulk solids

- Quality control and product certification

- Optimization of flow aids and/or processes

- Silo or bin activator design

- Time consolidation of bulk solids

- Ensuring mass flow in a silo

- Prevention of arching & determination of outlet opening

- Process control to prevent operational disruptions and/or damage

- Avoid product change issues

- ...

Rheological Bulk Solids Measurements

Take advantage of more than thirty years of experience in bulk solids analysis. All measurements are performed on standardized and certified instruments in our laboratory with professional expertise. This provides you with real physical material data necessary for characterization and as a basis for further technological calculations.

Consistently digitized and networked processes – from sample preparation through measurement to evaluation – ensure the highest quality and fast, cost-efficient execution.

- Yield Locus

ASTM D6682-A, angle of internal friction φi, effective angle of friction φe, cohesion τc, horizontal load ratio λ and λ0, unconfined compressive strength σc, flowability factor (FL, FLA, FLR or ffc),

+ Time consolidation

- Wall Friction

ASTM D6682-B, wall friction angle φw or φx, wall friction coefficient μw, adhesion τw,

+ Time consolidation

+ Wall surface changes

- Bulk Density, Compression Density

Bulk density ρb0, ρSch according to EN ISO 60; USP 616, Method III,

ASTM D6682-C bulk density function (compression density) ρb(σ),

ASTM D6682-A flow density ρbr(σr)

- Bulk Solid Moisture

%M (percent moisture), %S (percent solid), ...

- Angle of Repose

DIN ISO 4324, ASTM D6393

Bulk Solids Evaluations

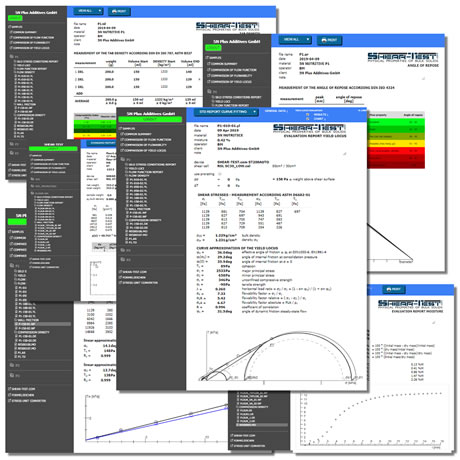

You receive the measurement results in clearly structured tables and informative graphics, making characterization and further calculations easier. Comparisons of bulk solid properties and frequently used bulk solid functions are automatically calculated and complement the evaluations. Our calculation tool enables you to specify various silo geometries and analyze the resulting stresses and flow profiles in the silo, so that potential problems can be identified early. Numerous evaluations and calculations are carried out in accordance with the specifications of DIN EN 1991-4 and support you in the optimal planning of your silo geometry.

- Raw data and evaluation of individual measurements

Yield locus, wall friction, bulk density, time consolidation, bulk solid moisture, angle of repose, tap density, ...

- Descriptive statistics of one and/or several bulk solids

- Yield locus envelope internal friction (linear and exponential)

- Function of effective friction angle φe(σ1)

- Flow function

σc(σ1), Flowability factor FL(σ1),

ffc(σ1)

- Density function ρb(σ1), Flow density

ρbr(σr)

- Influence of time consolidation

- Conveyor System Analysis

Calculation and evaluation of different conveying systems (screw conveyors, pneumatic conveying in dilute and dense phase), blockage risk assessment, power requirement calculation, operating parameter optimization based on material properties (φi, cohesion, density, flowability) - Silo calculation

Mean values including standard deviations SD, divergence coefficients aK, aμ, aγ, Silo classification according to DIN EN 1991-4, Silo stress calculation vertical pressure Pv, horizontal pressure Ph, wall pressure Pw in shaft and hopper for (active) filling state and (passive) discharge state, Limiting criterion for mass/funnel flow, Load at discharge, Arching in silo (critical outlet diameter), ...

Professional Contract Measurements for Powders & Bulk Solids

Do you need precise characterization of your bulk material? Our laboratory offers standardized measurements for safe silo design.

We are happy to advise you on the selection of appropriate tests according to your requirements. After receipt of the samples, we carry out the agreed measurements as quickly as possible and provide you with a comprehensive report with evaluations.

- ✓ Expert consultation

- ✓ Fast execution of measurements

- ✓ Comprehensive report with evaluations

- ✓ Personal support and review of results

- ✓ Recommendations for practical implementation